Door rolling shutter guide machine

Door rolling shutter guide machine is a automatic mass production of steel rolling shutter door, sliding door guide equipment.

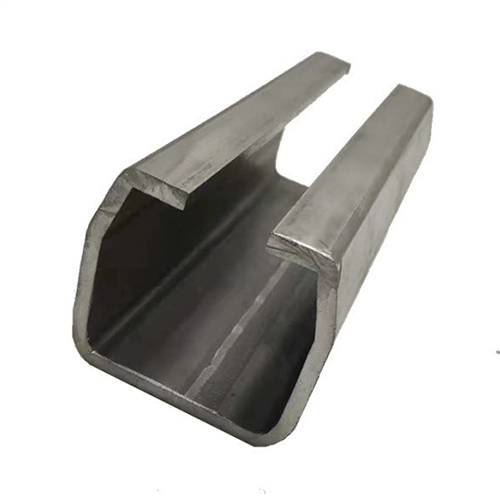

Door guide roller forming machine is used to make various guide rails. A guide rail, also known as a slide rail, is a device used to support and guide moving parts, and do reciprocating straight motion in a given direction. Our guide molding machines can make guides for garbage doors, rolling shutter doors, elevators or elevator shafts.

There are many more types of rails, we cannot list them all here. For rail-related profiles, Jinheng Machinery can provide you with the corresponding type of manufacturing machine. For different shapes and different requirements, we also have different designs in machine design.

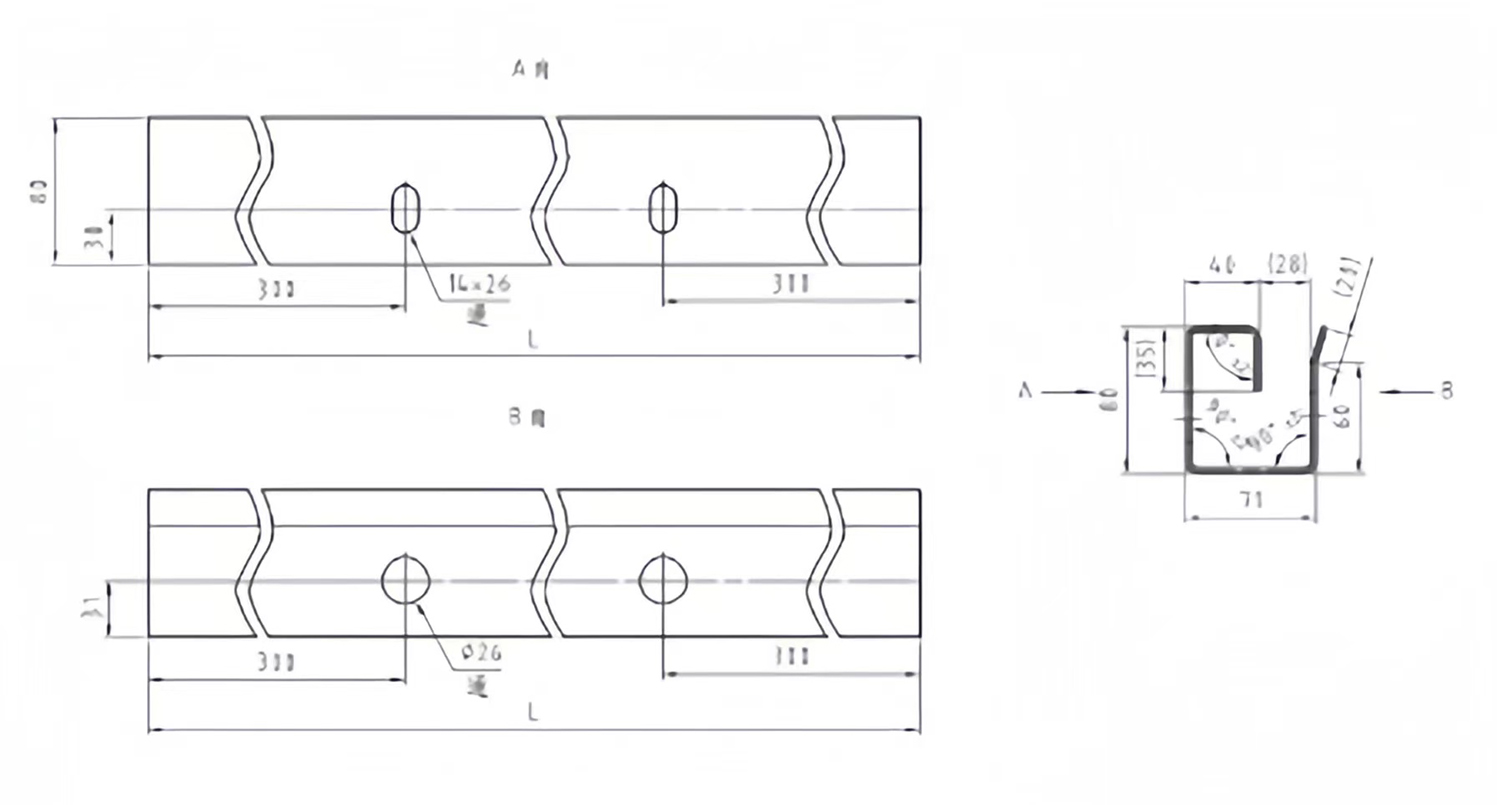

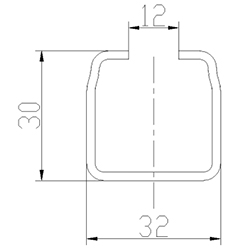

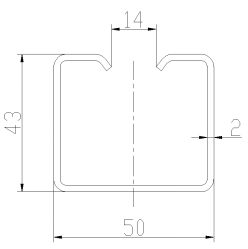

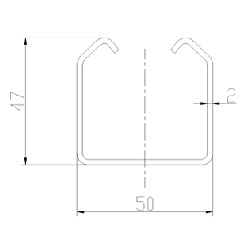

The following is the version of the rolling shutter door and sliding door guide rail:

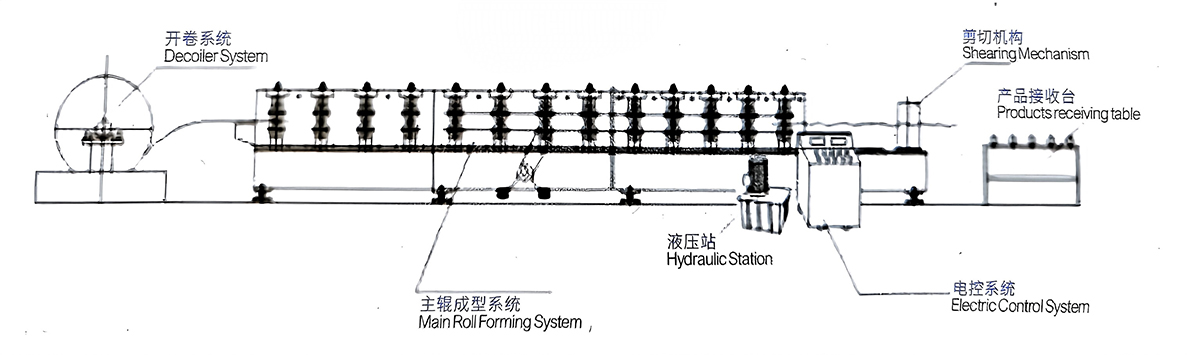

Working Flow

Unwinding → feed leveling → hydraulic punching (optional) → roll forming → hydraulic length cutting→output table

Our door with guide roller molding machine can also be prefabricated punching, if you need to contact us when you tell us, we can in the design time to add the punching function according to your requirements, all data are set in the PLC computer program.

If your production volume is large, our door guide roller molding machines can add servo motors and continuous tracking cutting at speeds of 14-20 m/min.

Introduction to some process components

Roll forming system:

- Thickness of raw material: 1.2 ~ 2.0mm; Material: galvanized coil;

- Number of molding rows: 20 groups or 22 composition types (select according to demand);

- Transmission type: chain or gear or gearbox transmission (according to design);

- Forming machine structure: plate or arch type (choose according to demand);

- Roller :GCr15 or Cr12 (according to design);

- Axis :45# or 40Cr; φ65 or φ70mm (depending on design);

- Molding speed: 8 ~ 12m/min (excluding punching);

Cutting type:

Cutting type: hydraulic cutting;

Hydraulic cutting after forming: cutting to the required length after rolling forming;

Cutting action: roll forming parts stop when cutting;

Blade material: Cr12 or GCr12MoV, quenching process, hardness HRC58-62 (as required);

Length tolerance: ±1.5mm;

Control system:

PLC system: Delta brand

Length controller: Cosenter or Omron encoder

Operation: touch screen

Inverter: Delta brand

Voltage :380 v / 50 hz/3P (according to customer requirements)

There are some other types of hanging rails for doors, such as those with anti-noise functions. If you need also can contact us, we have mature technology can provide you with stable performance, affordable equipment!