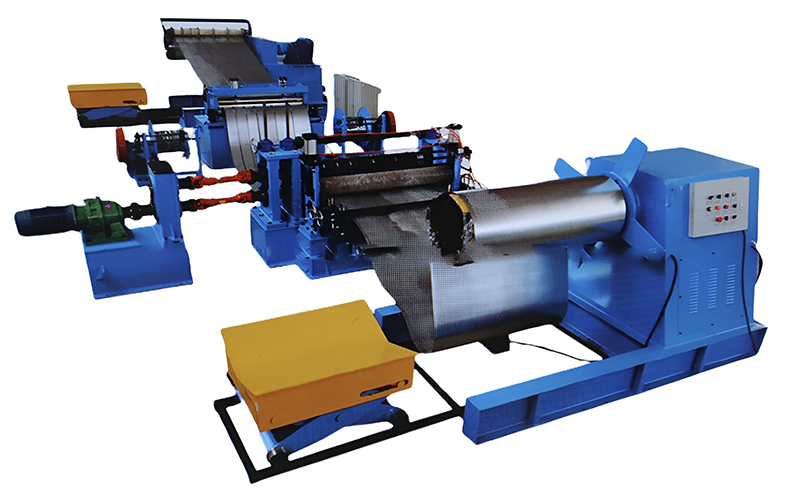

Sheet metal slitting machine

The sheet metal slitting machine is used to cut the steel coil lengthwise to the width and length required by the customer and rewind it.

Steel coil slitting line is a special equipment for unwinding, slitting and winding metal coil. The equipment cuts the metal coil into strips of various widths and collects them into small rolls for use in the next process.

What is the steel coil slitting line?

Slitting refers to the operation of cutting a wide strip into multiple narrow strips by the round tool or blade of the slitting system. The whole production line is composed of uncoiler, leveling system, shearing system, slitting system, waste winding system, damping structure and winding system.

Materials suitable for slitting:

Color coated coil, stainless steel coil, galvanized coil, aluminum coil, copper coil and other metal coil.

Working principle of sheet metal slitting machine

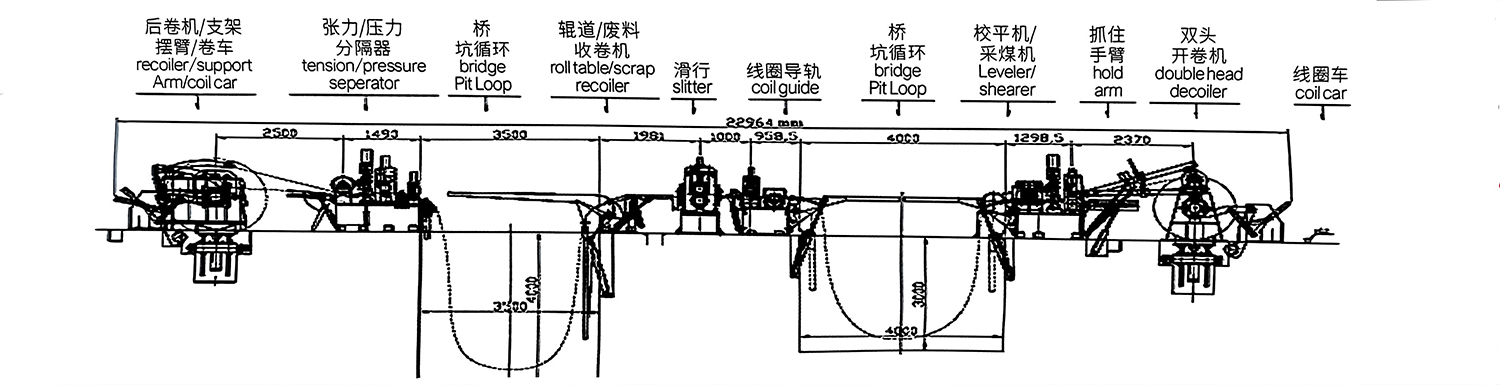

The steel coil slitting production line is designed according to the difference of metal material and plate thickness. We take ZJX-(1-3)x1250 night pressure slitting production line as an example to introduce it.

Uncoiling → feeding device → guiding device → Slitting machine → tightening device → winder → discharging machine

Main components of the production line

| NO. | Device name | unit | quantity | remark |

| 1 | Hydraulic loading trolley | Taiwan | 1 | 10 ton class |

| 2 | Hydraulic support uncoiler | Taiwan | 1 | 10 ton class |

| 3 | Transition device | Taiwan | 1 | |

| 4 | Deviation correcting device | Taiwan | 1 | |

| 5 | Slitting machine | Taiwan | 1 | (1.0-3.0) x 1250 |

| 6 | Scrap reel | Taiwan | 1 | |

| 7 | Roller separation and compression device | Taiwan | 1 | 500mm—1250mm |

| 8 | Tightening mechanism | Taiwan | 1 | 500mm—1250mm |

| 9 | Separation device | Taiwan | 1 | 500mm—1250mm |

| 10 | Winder and auxiliary support device | Taiwan | 1 | 10 ton class |

| 11 | Discharge car | Taiwan | 1 | 10 ton class |

| 12 | Hydraulic system | Set of | 1 | Pressure: 16MPa |

| 13 | Electronic control system | Set of | 1 | PLC, frequency conversion control |

Introduction to the components of the production line

Ransition device and material pit

The transition device is composed of structural parts and welded steel. It is placed in the pit between the uncoiler and the correction servo feeding unit, and is lifted by the oil cylinder to reserve and transport the plate material.

Pit: users take care of themselves, for the reservation of the board, the two sides of the pit with a circular transition roller frame, can protect the board from scratch.

Anti-deviation device

The machine is welded by section steel and is designed for conveying plate material. It is convenient for the plate material to enter the slitting machine smoothly. Two deviation correction devices are provided on this equipment to smoothly slitting after the plate material is found right, so as not to damage the plate material and equipment.

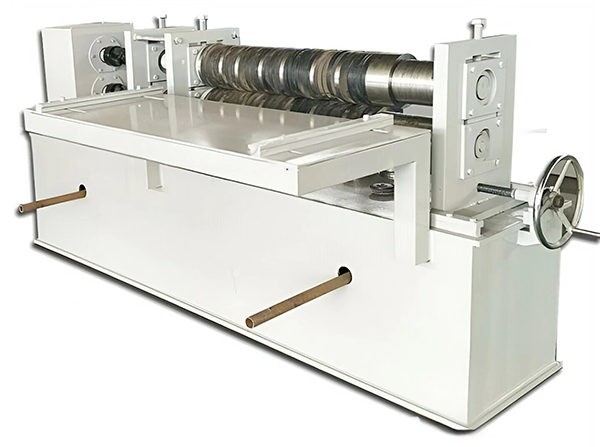

Slitting unit

The slitting machine is an important equipment in the production line, which mainly trims and slitts the coil plate according to the width requirements.

Scrap reel

The function of the equipment is to collect the waste edge wire that has been cut on both sides after the longitudinal cutting of the coil plate.

Roller compaction device

Two rollers grip the steel strip, trim the edge of the steel strip and provide winding force.

Hydraulic resistance tightening mechanism:

The unit through the lifting of the cylinder, synchronous rack control to implement positive pressure on the steel plate, play a role in blocking the reverse tightening.

Platform before receiving material

Frame type structure, easy to transition feed before winding, hydraulic cylinder control lifting height.

Separation tightening device:

The divided steel strip is neatly separated to facilitate the winding machine to better and neatly pack up the steel strip.

Winder and auxiliary support device

It is convenient to close the steel strip divided by the disc shear according to different specifications;

Discharge car

With the function of moving up and down, it is convenient to move the steel strip from the push device inside the coiler to the expansion claw;

Features of sheet coil cutting machine

Our company has rich experience in slitter design, for slitter equipment, I use advanced production technology and processing technology, so that our production of slitter has the characteristics of simple operation, stable and accurate production capacity, can greatly improve production efficiency and product quality, reduce labor input and production costs.

If the steel coil does not have high requirements for slitting speed and precision, the equipment can be simplified, but this is only applicable to thin steel plates.