1.Introduction

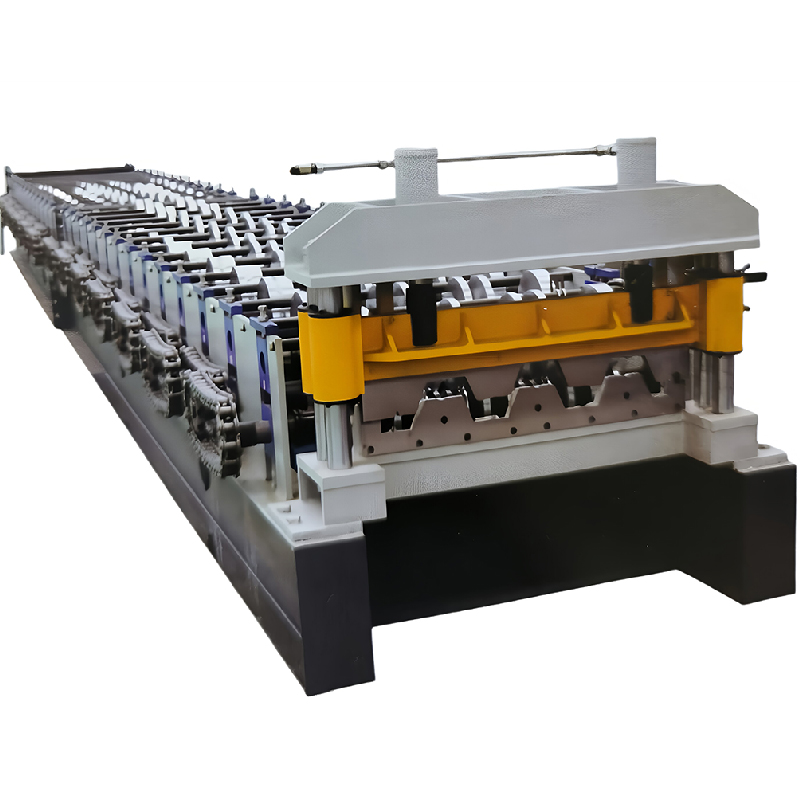

1.1The main forming process of the roof steel sheet

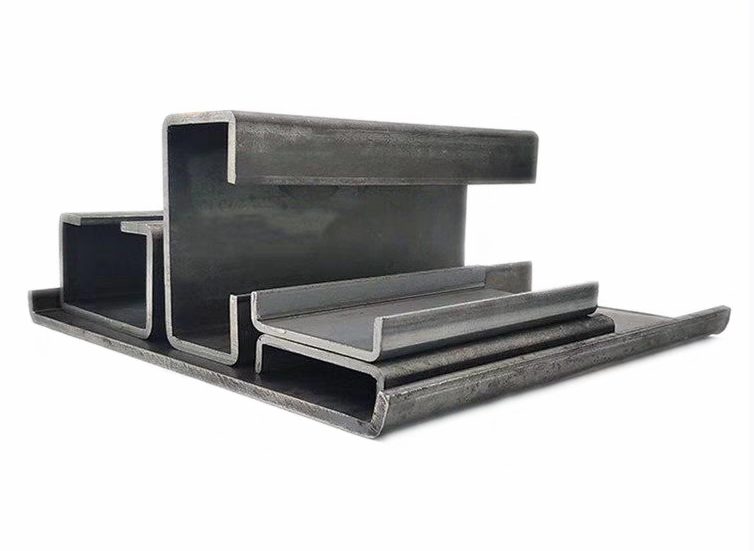

2. Different type of roll forming profiles

2.1 C-Shaped Profiles (Channels)

2.2 Z-Shaped Profiles:

2.3 U-Purlin Profiles:

2.4Hat-Shaped Profiles:

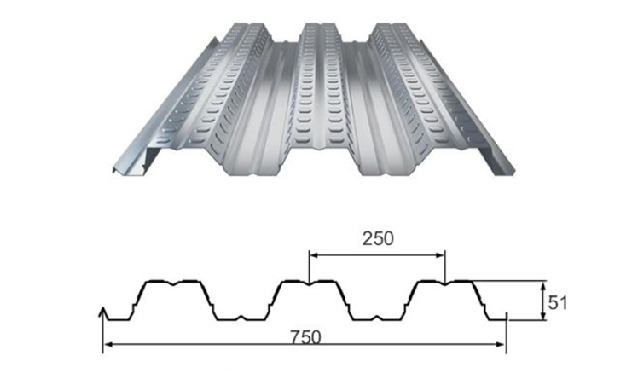

2.5 Decking Profiles:

2.6 glazed roof tile Profiles:

2.7 PBR Profile:

Introduction

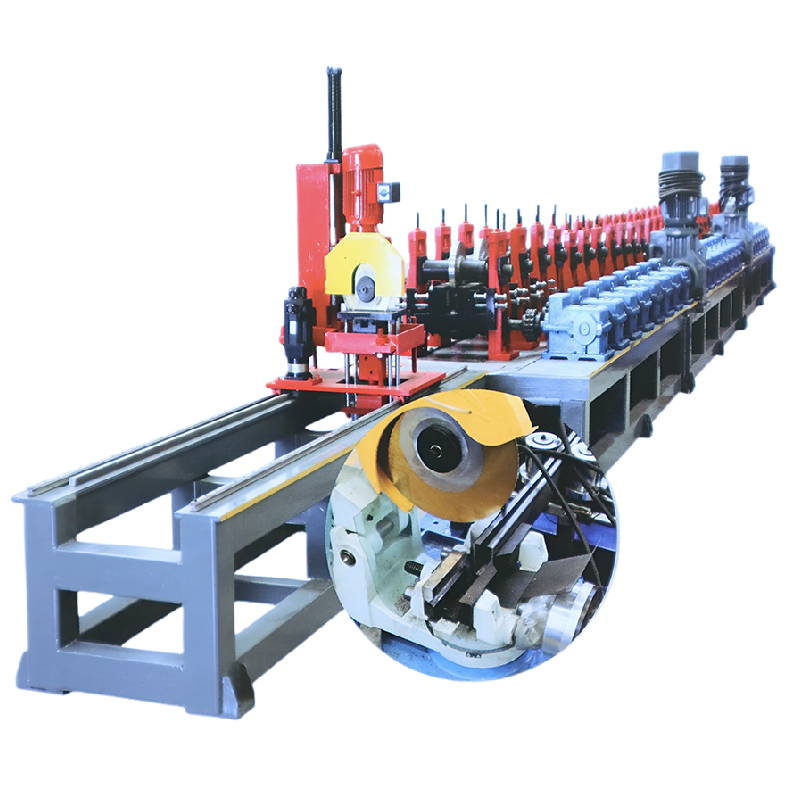

The main process of roll forming is to gradually form the required steel sheet into the desired shape through a series of rollers.

In rollforming, we manufacture aluminum profiles from strip material through a continuous process. The aluminum strip passes through a sequence of precisely shaped rolls, which gradually form the profile into its desired shape. Multiple operations, such as embossing, notching, decorating, hole punching, and bending, can occur simultaneously during this process.

This efficiency minimizes or eliminates the need for refinishing, distinguishing rollforming from other production methods like extrusion or squaring. As a result, we can achieve shorter production times, delivering large volumes of products quickly, consistently, and with a high degree of precision.

The main forming process of the roof steel sheet is:

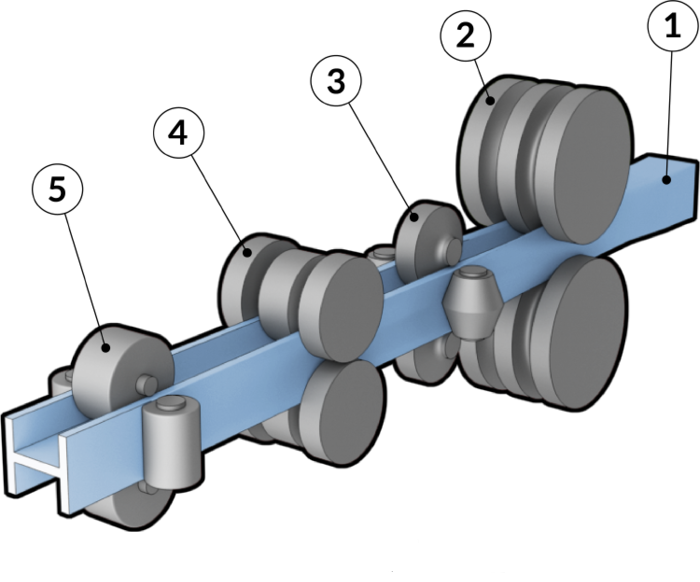

First, the steel coil passes through the feed port and then enters a pair of rollers [2] to form a simple shape. Then, the beam passes through a multi-purpose roller pair [3], which has horizontal and vertical rollers that can be adjusted according to the required profile. Edge rollers [4] ensure that the upper and lower surfaces of the beam are parallel. The beam finally passes through another pair of multi-purpose rollers [5] to push out the final profile.

Please send us your profile drawing and size. We can design and produce the machine according to your drawing. If you don’t have a drawing, we will give you a quotation based on our standard profile.

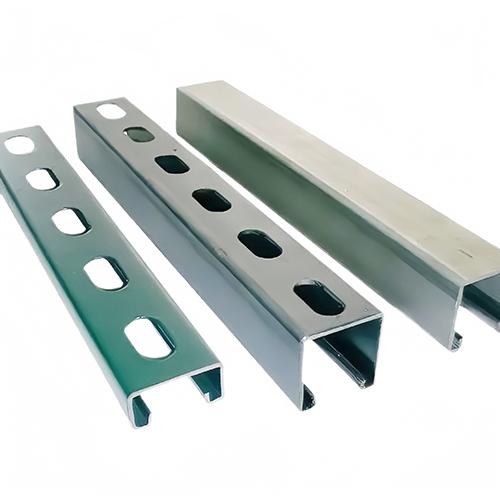

C-Shaped Profiles (Channels):

- Channels are widely used for structural applications in construction and industrial settings.

- They have a distinctive “C” shape with varying dimensions and thicknesses to suit different load-bearing requirements.

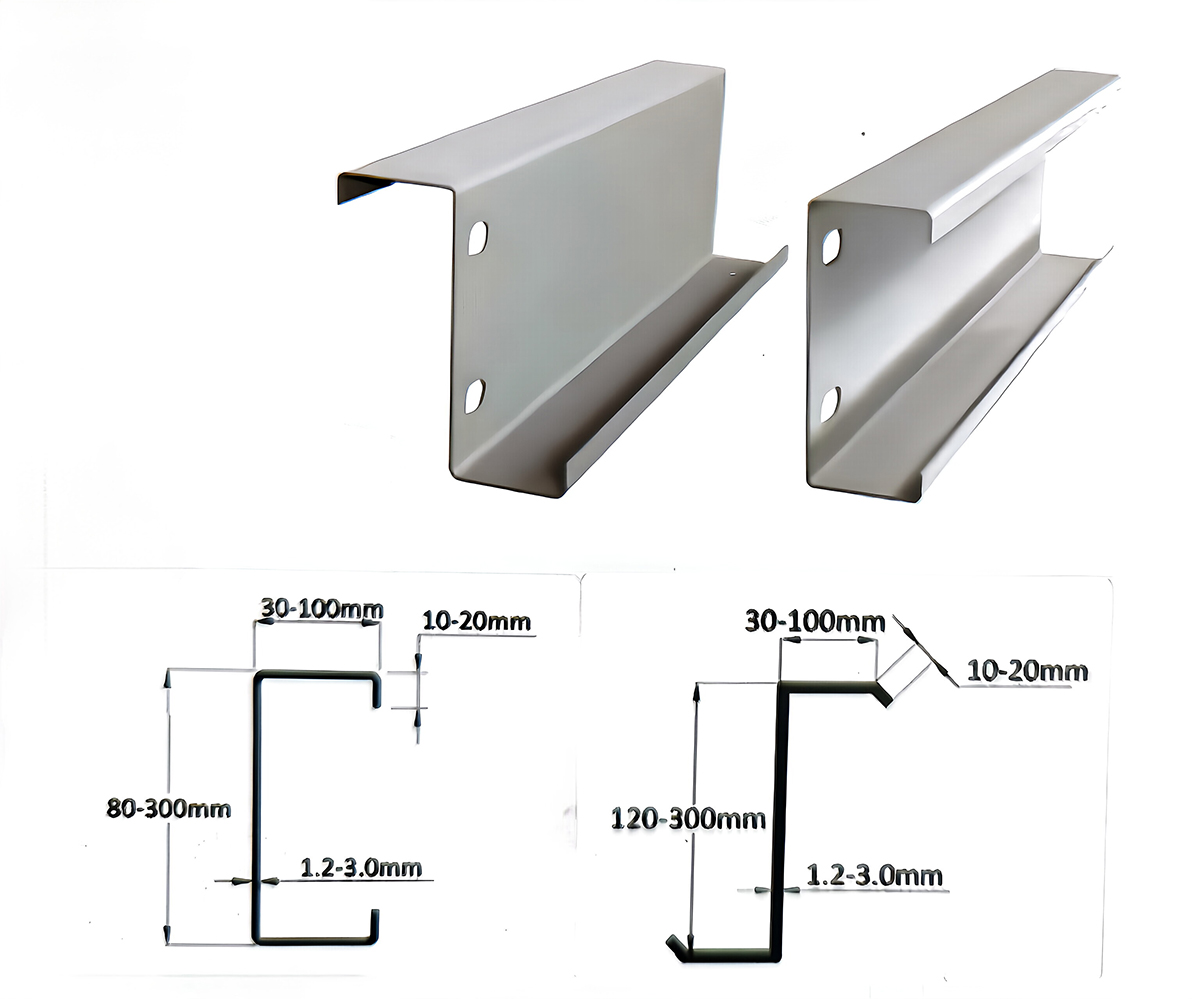

Z-Shaped Profiles:

- Z-profiles have a zigzag shape and are commonly used as purlins and girts in construction.

- They provide structural support and can span large distances with minimal weight.

U-Purlin Profiles:

- U-profiles, also known as U-channels or beams, have a “U” shape and are used for structural support and framing in buildings and machinery.

- They offer strength and stability, often used in industrial and architectural applications.

Hat-Shaped Profiles:

These profiles resemble the shape of a hat (hence the name) and are used for various structural and framing applications.

Hat sections offer strength and versatility, often used in roofing and wall framing systems.

Decking Profiles:

- These profiles are designed for use in composite steel floor decking systems.

- They provide efficient structural support and act as a formwork during concrete pouring in construction.

glazed roof tile Profiles:

A roof tile profile refers to the shape and design of the tiles used in roofing. These profiles not only impact the aesthetic appearance of a roof but also affect the way the roof performs in terms of water drainage, durability, and weather resistance

PBR Profile:

A PBR roof tile profile typically refers to a metal roofing profile, commonly associated with the PBR (Panel Rib) metal panels, rather than traditional clay or concrete roof tiles.

PBR panels are often used in both commercial and residential roofing applications and are known for their durability, versatility, and ease of installation.

Roll forming is a manufacturing process used to shape metal sheets into desired profiles by passing them through a series of rollers. Each set of rollers gradually bends and forms the metal until the desired shape is achieved. This process is highly efficient for producing consistent and complex profiles with minimal waste. Roll forming finds extensive application in industries such as construction, automotive, aerospace, and appliances, where customized profiles are needed for various structural and decorative purposes.