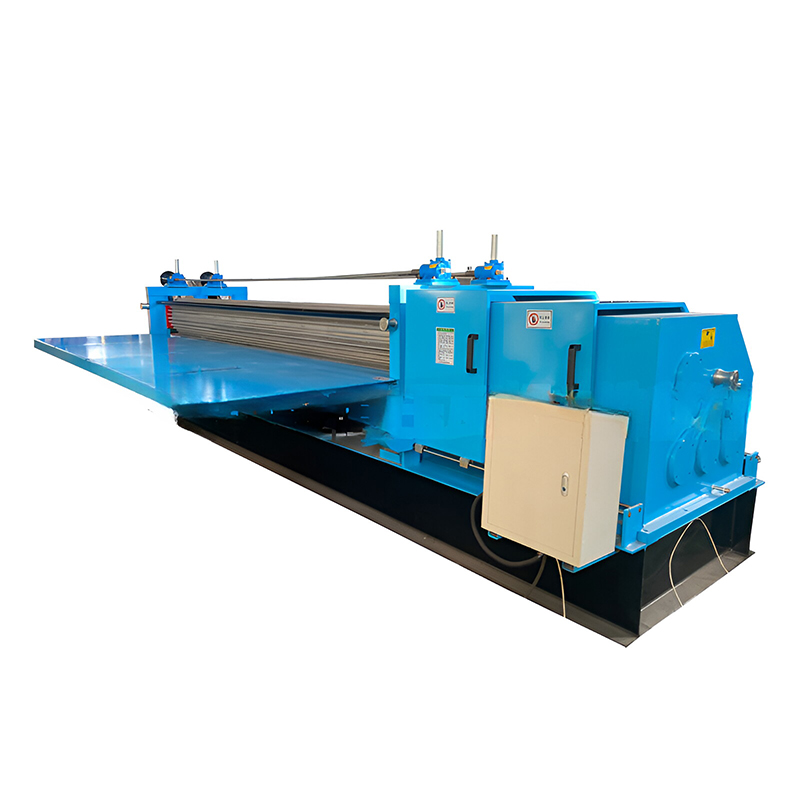

Horizontal wave roof sheet machine

Horizontal wave roof panel machine is a kind of automatic mass production of a variety of wave roof panel equipment.

What is Horizontal wave roof sheet machine?

In South Africa and some regions, people prefer to use thin sheets between 0.13 and 0.2 mm in thickness to make metal roofing panels. Due to the limitations of the roll forming machine, the material of this thickness cannot be produced by the roll forming machine, otherwise it will tear into pieces.

According to this demand, our company has designed and developed on the basis of the traditional rolling forming machine, and produced the horizontal corrugated roofing machine that rolls thin sheets into roofing panels. The equipment can process materials from 0.15 to 0.30 mm thick, and the length of the roof panels can be customized according to the individual needs of the customer. However, due to the limitation of rolling method, the equipment needs to be manually loaded and unloaded.

Technical Parameters

| No. | Item | Parameter | Remark | |

| 1 | Material | Type | PPGl; full hard, semi hard, soft. | As requirement |

| Thickness of Material | 0.15-0.3mm | As requirement | ||

| 2 | Material Width | 3 meters, 4 meter or 6 meters | As requirement | |

| 3 | Length | can be customized | ||

| Production Speed | 10-15 pieces/minute | As requirement | ||

| 4 | Axis Diameter | 450mm | As design | |

| 5 | The movable range of the feeding platform | 750-1200 mm | As design | |

| 6 | Motor Power | 7.5kW | As design | |

| 7 | Control method | The electric control box can adjust the positive and negative rotation and speed regulation | As design | |

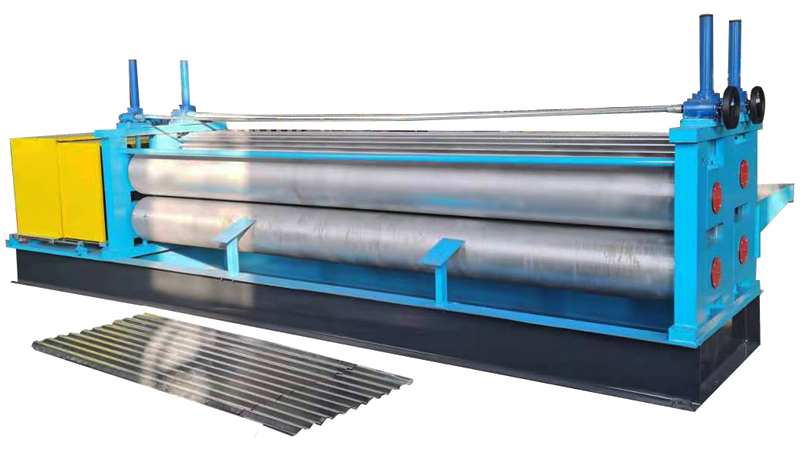

Working principle

Manual feeding → rolling molding → Finished roof panel output

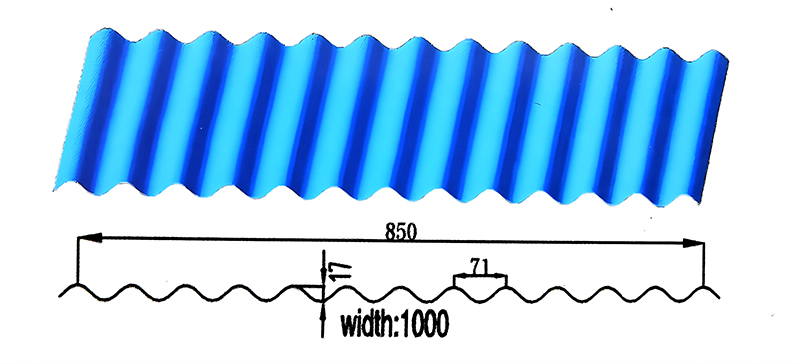

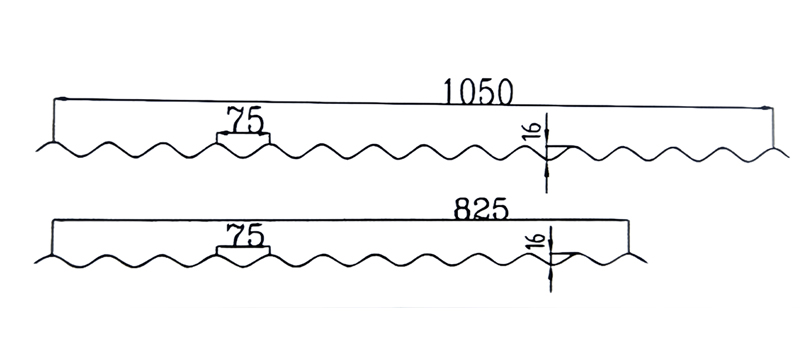

The following are drawings of conventional wavy roof panels:

Using this type of roller corrugator, you first need to cut the long sheet into small segments of the desired length, and then feed the coil into the machine segment by segment.

Common problems when using horizontal circle waveform forming machine:

- The R Angle is too small, and the arc feels abrupt and unattractive.

- The position of the wave crest is wrong, and the arc length on both sides is different.

- Edge rebound: the smaller the edge, the more difficult to press, and the thinner the edge, the more difficult to press.

How do we solve this problem?

- Improve the hardness and accuracy of shaft processing.

- Handle equipment carefully.

- If you wish, we can also use the gearbox as the transmission mode, but the price will be slightly higher.

Features

Our company has rich experience in the design of roller forming machine. For this roller corrugation equipment, we adopt advanced production technology and processing technology, so that the horizontal circular waveform equipment produced by us has the characteristics of simple operation, stable and accurate production capacity, which can greatly improve production efficiency and product quality, and reduce labor input and production costs.