Prefabricated container house framing machine

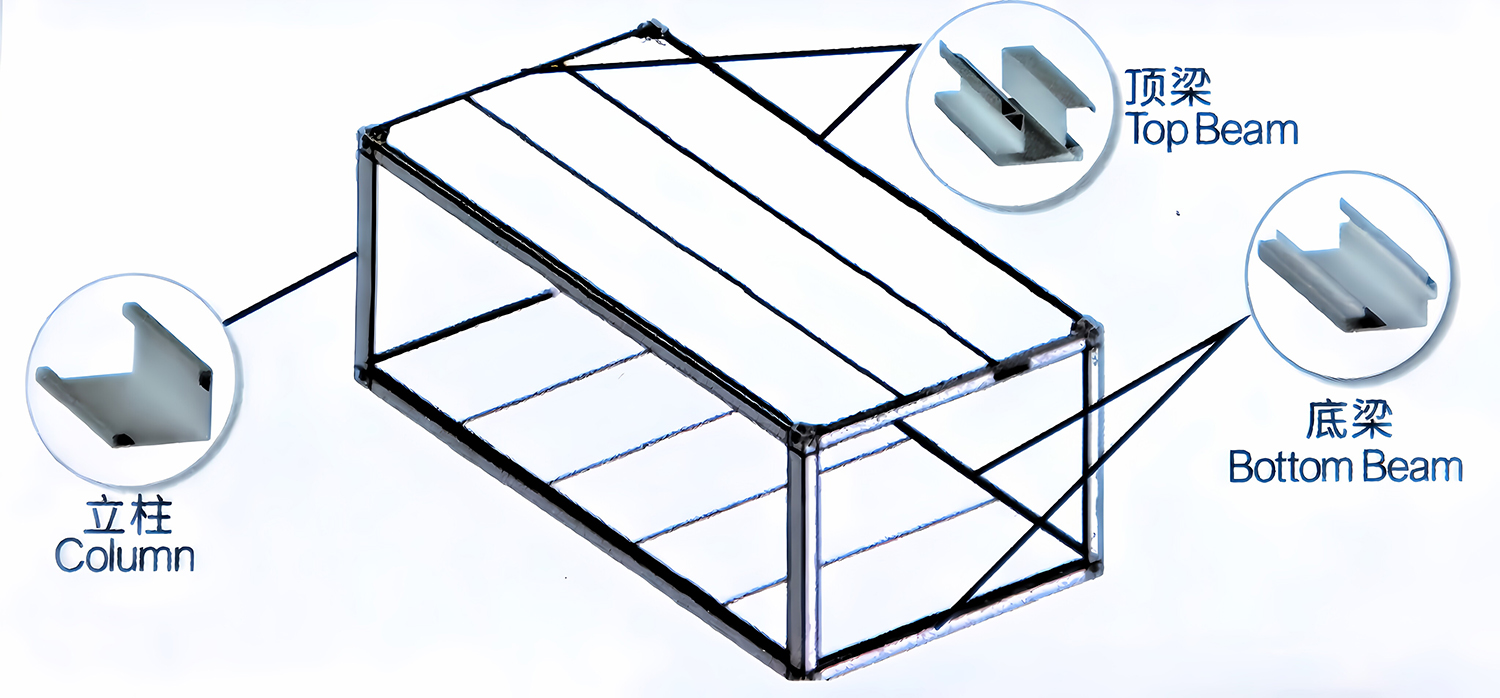

Prefabricated container house frame equipment is the automatic mass production of prefabricated container house frame columns, beams, bottom beams and other profiles of the equipment.

Request A QuotePrefabricated container house frame equipment is equipment designed for mass production of house frames, and the size and thickness of the house frame produced by the equipment can be adjusted and customized.

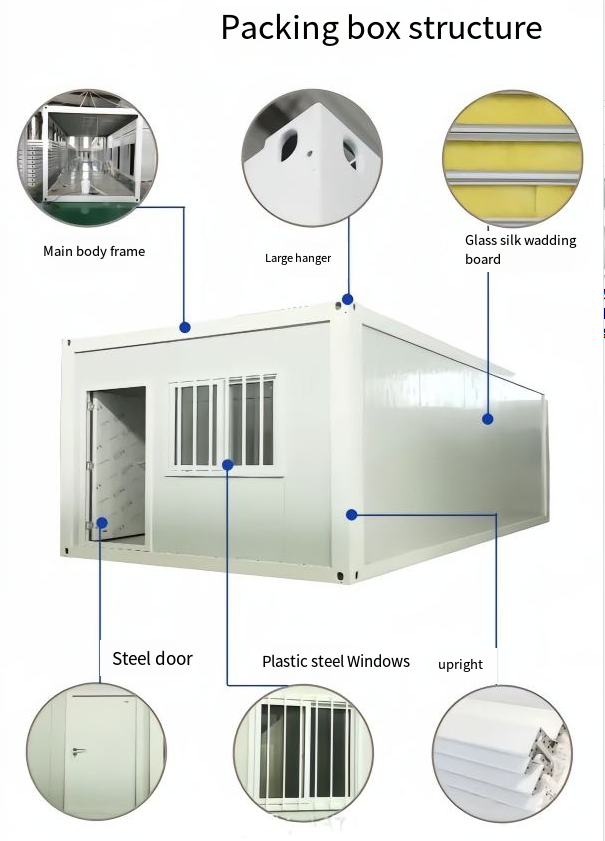

Prefabricated container house, also known as rapid splicing container house, is a prefabricated building, which is not only simple in structure, but also very convenient in installation. All kinds of houses can be quickly built after the container is transformed and spliced. Compared with the traditional brick-concrete structure, the installation speed of prefabricated container houses is much faster, which can greatly save the construction cycle, and is very beneficial for projects that urgently need to be placed on the ground.

Because of these advantages of the house, prefabricated container houses are widely used in multi-storey (2-3 floors) and high-rise buildings with a height of 15m or less. For example, mobile offices, construction site dormitories, medical and health, leisure and entertainment, education fields, residential villas, mobile security posts, temporary headquarters, temporary exhibition halls, etc., prefabricated container houses are used to build. It brings great convenience and thoughtful service to people’s life and office.

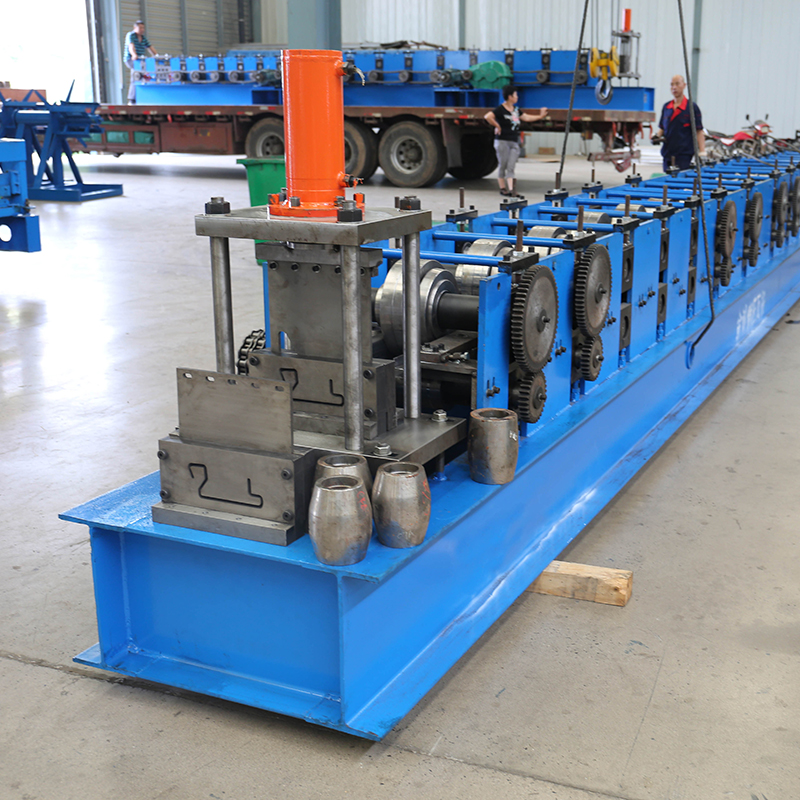

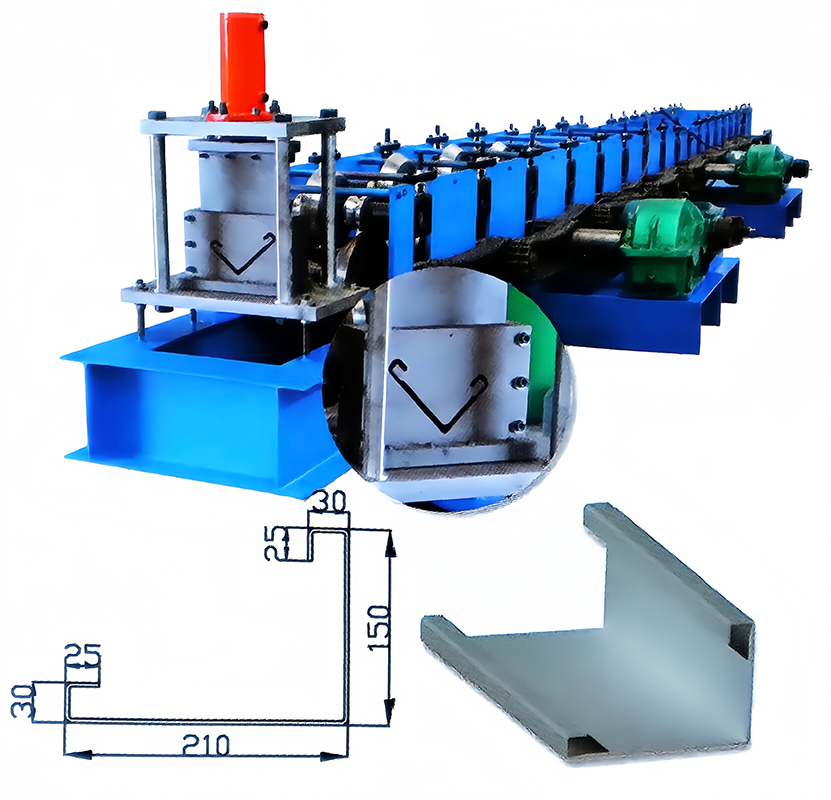

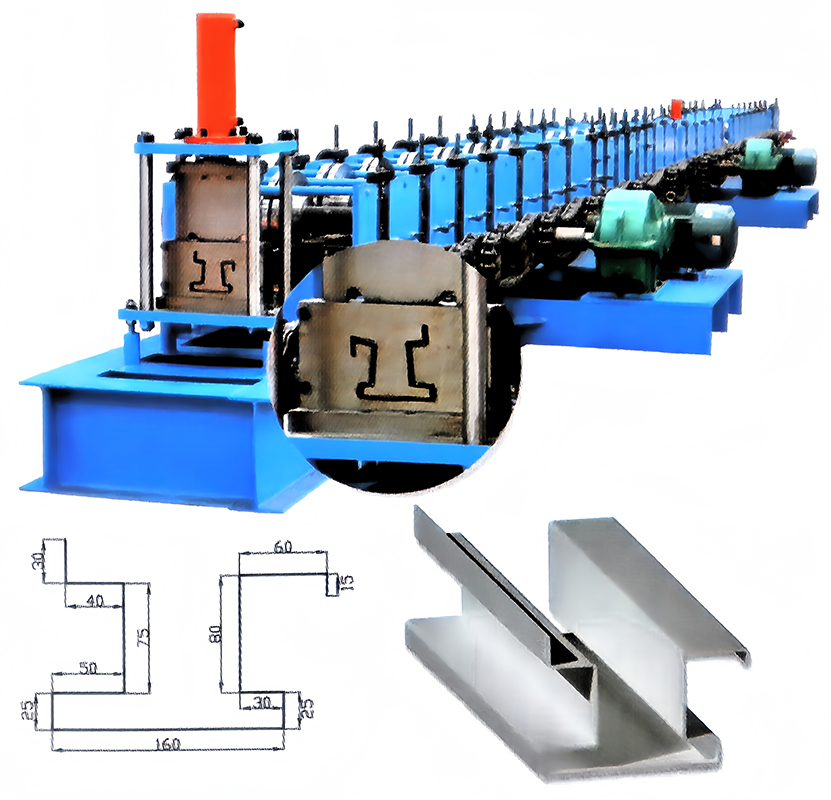

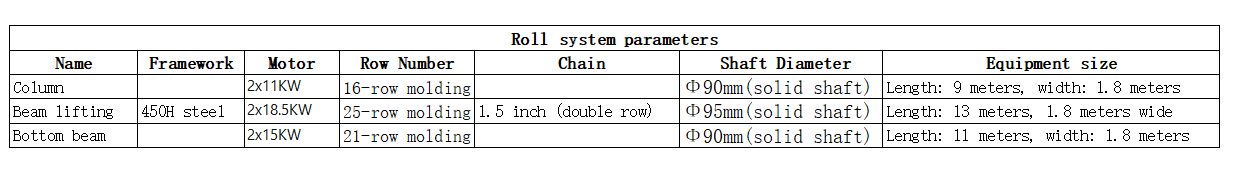

Different type of Prefabricated container house framing machine

Bottom beam equipment

Column equipment

Beam lifting equipment

If you have your own design scheme, provide us with your design drawings, our engineers can give a good suggestion. If you have any ideas for your new project, you can get some professional ideas from us.

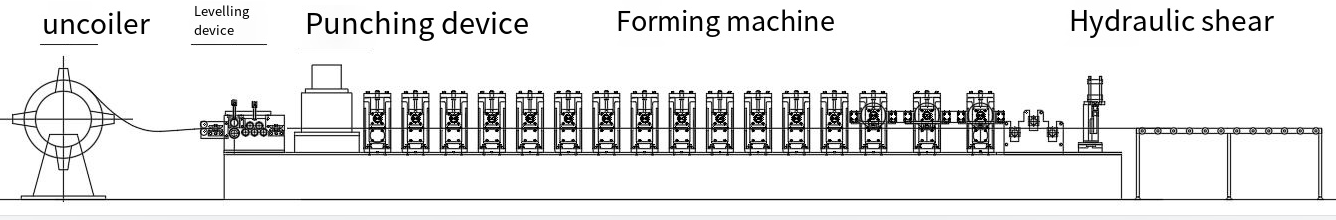

Working Flow of container house framing machine

Unwinding → feed leveling → hydraulic punching (optional) → roll forming → hydraulic length cutting→output table

Main components of the production line

- Uncoiling machine

- Feed and smooth

- hydraulic punching (optional)

- roll forming system

- Cutting device

- Control system

- Output workbench

Roll forming system:

Our company has a wealth of experience in the design of roller forming machine, for the forming machine equipment, I use advanced production technology and processing technology, so that our production of automatic forming machine has simple operation, stable and accurate production capacity characteristics, can greatly improve production efficiency and product quality, reduce labor input and production costs.

Our company to provide customers with professional and efficient after-sales service and one-stop solutions! Our after-sales service purpose is the fastest way to solve the problem, the best way to solve the problem, the best attitude to solve the problem.