Wall panel making machine

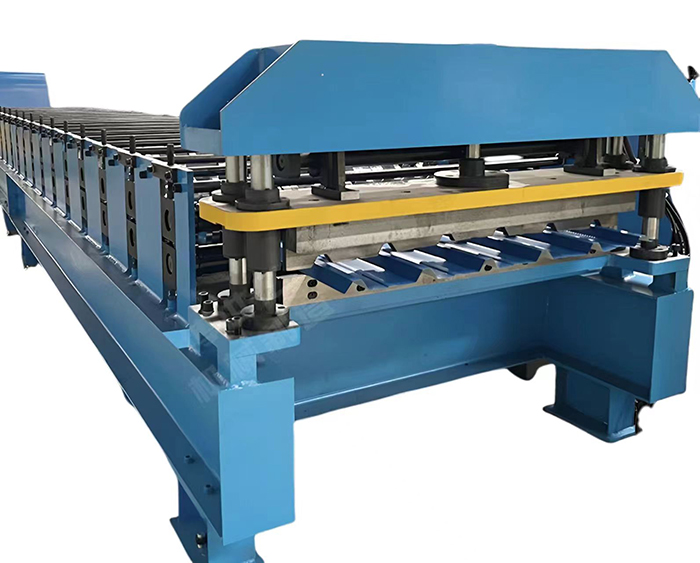

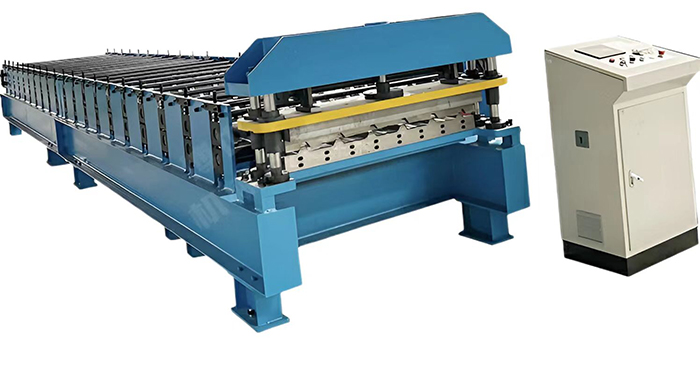

Wall panel making machine is automatic mass production of metal wallboard equipment.

Wallboard making machine can also be called metal wallboard rolling forming machine or wall protection board equipment. There are several common types and forms of wallboard, and their types vary in material and size. The following are several commonly used wall panels produced by our company’s equipment.

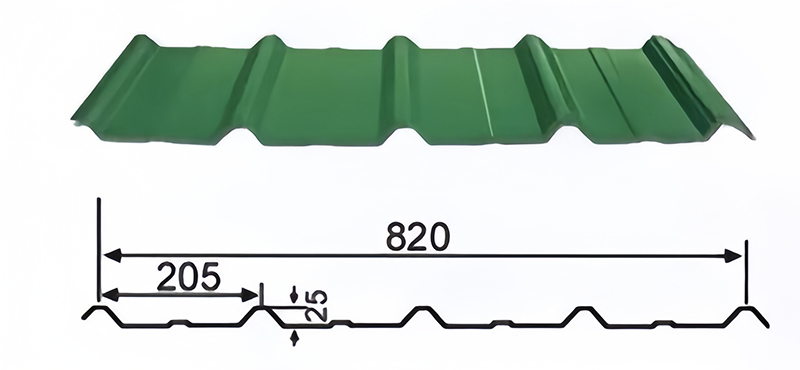

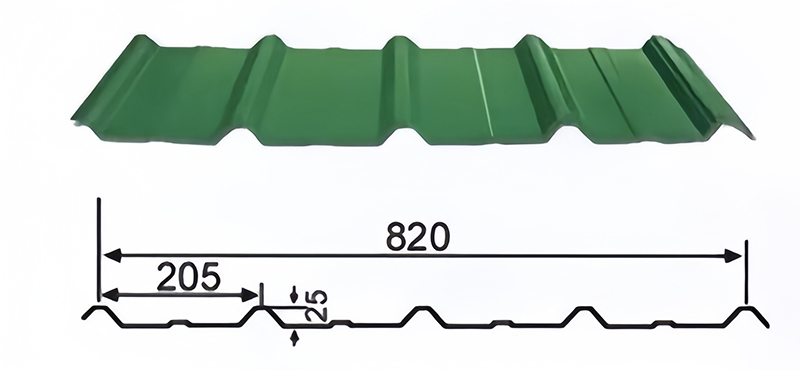

Type 820 metal siding

The effective width of this type of wall panel is 820 mm, the thickness of the material is 0.3-0.8 mm, which is a popular model, suitable for light steel structure, concrete, brick wall and other different types of buildings, with good characteristics of fire, corrosion resistance, earthquake resistance and waterproof performance.

Type 880 metal siding

The effective width of this type of wall panel is 880mm, and the thickness of the material is 0.27-0.8mm, which is a new type of hidden interface model, mainly suitable for industrial plants, commercial buildings, stadiums and other high-end construction fields.

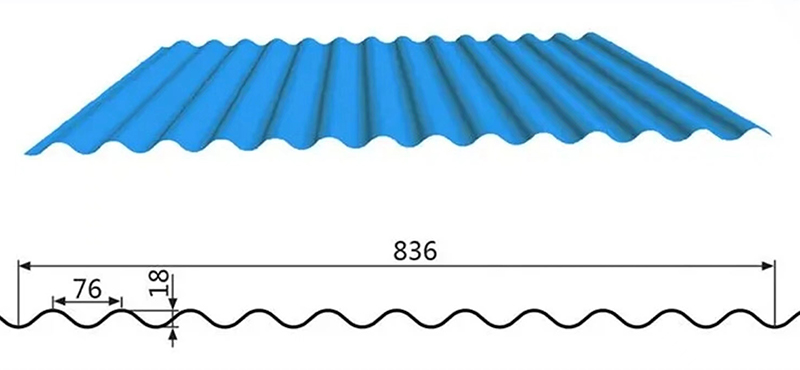

Type 836 metal siding

The effective width of this type of wall panel is 836mm, the thickness of the material is 0.27-0.8mm, the type of wall panel adopts the gap connection method, and makes a color coating on the board surface, beautiful and generous, can be used for the exterior wall decoration of villas, hotels, RV and other buildings.

Type 750 metal siding

The effective width of this type of wall board is 750mm, the thickness of the material is 0.3-0.8mm, because its plate type is like tile, also known as metal tile wall board, with easy installation, light weight, strong fastness and other characteristics, suitable for new environmentally friendly and low-carbon buildings.

Concealed metal wall panel rolling forming machine

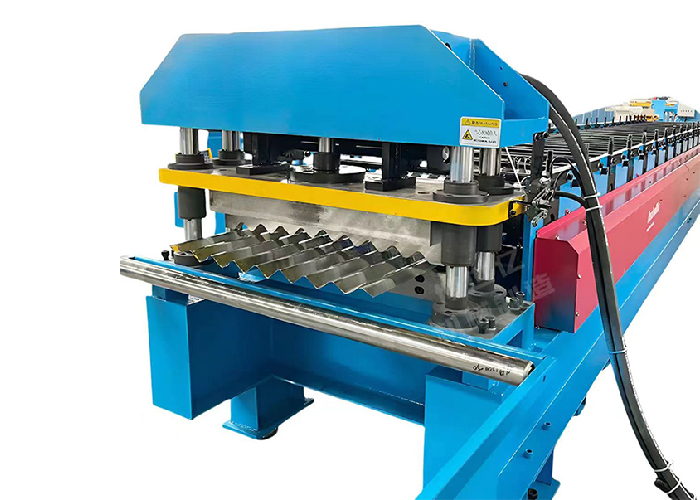

Concealed metal wall panel rolling forming machine is designed for automatic mass production of concealed metal wall panel and roof panel. Concealed metal wall panels and panels are installed in a hidden type, and the system surface is screws free, which can prevent leakage in any harsh climate, and overcome the displacement of the plate and fixed support due to thermal expansion and contraction. A variety of metal materials are available for rolling molding.

We can also customize stainless steel and aluminum alloy material special wall panel making machine. Compared with color steel wall panels, the cost of these materials is higher, but stainless steel wall panels and aluminum alloy wall panels are more durable and have longer service life than color steel wall panels. Our company has a wealth of experience in the design and production of stainless steel and aluminum wall panel forming machines, we produce wall panel forming machines less maintenance or replacement times. Stainless steel and aluminum wall panels are mainly used in the basement and storage walls of buildings and large commercial buildings and structures, even after a long time, these wall panels are as good as new.

Features of floor roll forming machine

Color steel tile is characterized by light weight, high strength, good water resistance and long durability. In construction, some color steel tile is usually used as a roof covering material, but can also be used as a wall material, but some color steel tile is not a wall dedicated tile, need to be selected and designed according to the specific situation.